When to use 4043 and when to use 5356 for TIG welding aluminum

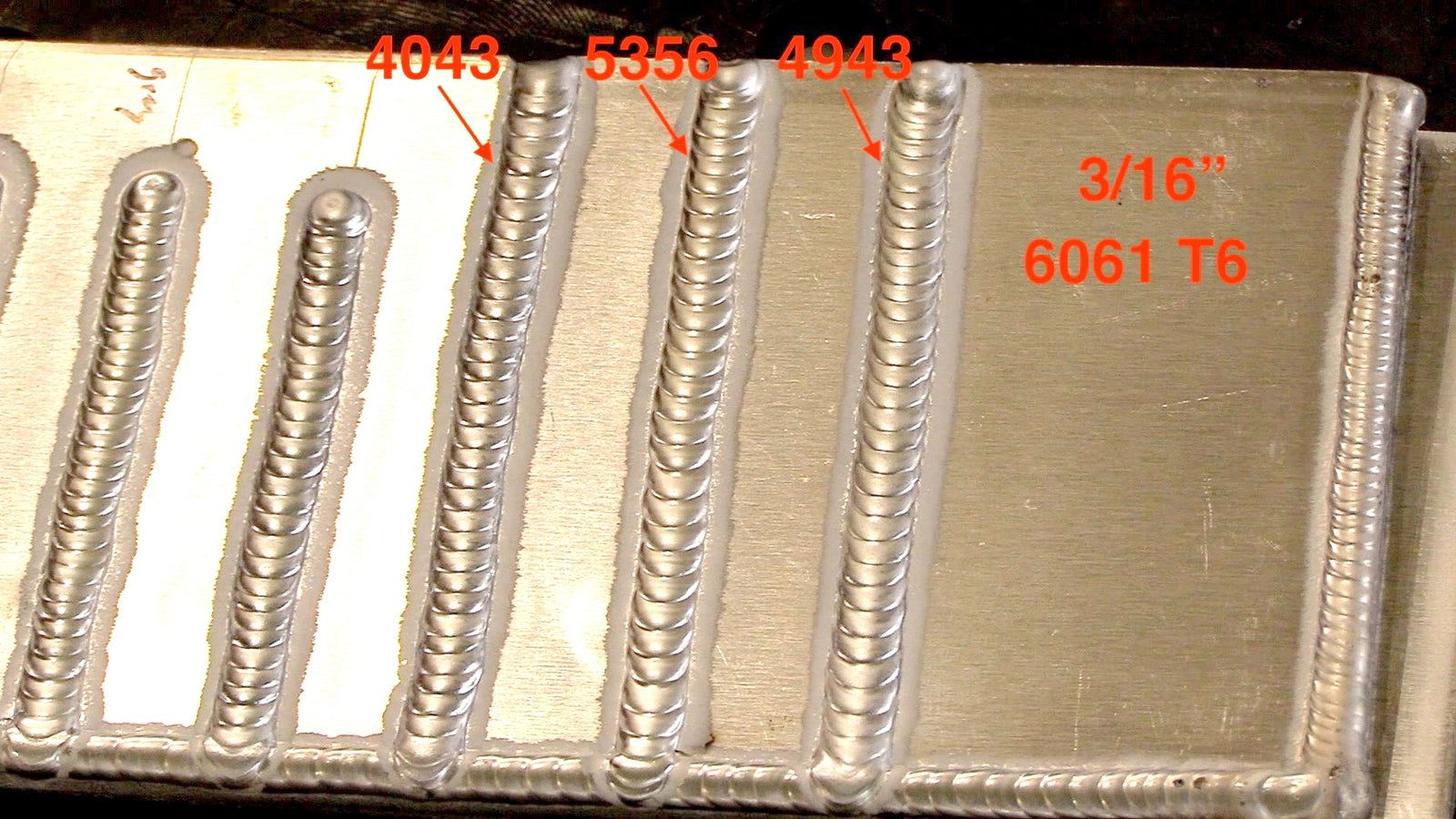

4043 and 5356 are by far the 2 most commonly used filler metals for tig welding aluminum.

If fact, according to this handy Hobart Filler Metal chart, 85% of the filler metal they sell is either 4043 or 5356.

And by the way, Hobart Filler Metal chart is a great resource and I highly recommend you download it.

So how do you know which filler rod will work better for the job at hand?

And when would other aluminum filler rods like 4047, 4145, or 4943 be a good choice?

Before we dig into it... I have a special deal going on until 10/7/24.

First lets use 6061 aluminum as an example because 6061 aluminum can be welded with either 4043 or 5356 and also few other filler rods like 4047, 4145, and 4943.

Often times, selecting a filler metal that is the closest match to the metal being welded is a good practice. But not always.

With aluminum, there are other factors to consider.

Filler metal choice for 6061 aluminum depends on a few key factors like:

Crack sensitivity, strength, ductility, corrosion resistance, elevated temperature service, color match after anodizing, post weld heat treatment, and toughness.

Another factor is of course engineering documents or specifications.

Let's break all these factors down a bit one by one...

Crack Sensitivity. The chemistry of the filler rod affects the likelihood of cracking.

that is why 6061 is usually welded using either 4043 or 5356 filler rods. Welding 6061 with 6061 filler rod is difficult to do without getting cracks.

Strength. Strength is always a consideration when selecting a filler rod. 5356 is stronger than 4043 but strength is just one of many factors to consider.

Ductility. A ductile weld can flex more without cracking

Corrosion Resistance. since aluminum is often selected as a material for its resistance to corrosion, selecting a filler metal with similar corrosion resistance to the base metal is another factor.

Elevated temperature service. If a part will be subjected to temperatures above 150F, stress corrosion cracking can occur if the wrong filler metal is selected.

Color match after anodizing. When welding 6061 aluminum, 4043 and other high silicon filler rod welds will be dark after anodizing. 5356 responds to anodizing treatment better and is a good color match after anodizing.

Post weld heat treatment. Sometimes engineering documents require a post weld heat treatment to strengthen the weld. Only certain filler rods will respond to a strengthening heat treatment.

Toughness. toughness is a metals ability to withstand impact without cracking. Toughness is the opposite of brittleness. For example, cast iron lacks toughness and can easily be cracked by a blow with a hammer while aluminum is tough enough to absorb a blow without cracking.

Engineering Specs and documents sometimes make the choice for you.

Sometimes aluminum welds are made according to a code or specification and have a written welding procedure to follow that specifies what filler metal is used. In this situation, the engineer has already selected the filler metal based on the most important factors.

For most of us in our garage, we make the decision and so we need to think about the most important outcome.

Will the part be anodized after welding?

If the part will be anodized, realize that welds made with 4043 won’t respond well and will be very dark and will stick out like a sore thumb so a filler metal like 5356 is often used.

Will the part be subjected to temperatures above 150f during service?

Welds made with 5356 can be crack sensitive when exposed to temperatures above 150F. (All the technical books and articles state this and yet there are folks who repair cylinder heads who swear 5356 works great and holds up well ).

Is the weld a fillet weld or butt weld?

While 4043 flows better, 5356 filler metal is stronger and tends to hold up better for fillet welds.

There are several other factors that might be considered when choosing a filler rod for aluminum but for me, it usually boils down to this...

What is my most important result?

Sometimes it could be a combination of things.

In the case of 6061, it might be both strength and color match after anodizing.

For Aluminum castings, it might be lack of porosity and 4047 might be a great choice for a casting.

Once again, this Hobart Filler Metal chart is a great resource and I highly recommend you download it.

3 comments

Jody! Thank you for a fine video on the various aluminum rods. As a self taught welder (with your video assistant), I am now producing respectable welds, even as assess by pros and secured addition jobs for my machine shop.

You produce the finest, most detailed videos out there, I cannot thank you enough!

My supply shelves are full right now but I know were to go when I need more!

Please stay well, SR

Jody

Great simple explanation!!

Thanks so much

OSS AUSTRALIA. NB. c13% silicon aluminium as braze or as 400 series casting is most fluid & searching the braze has remarkable mechanicals !!! The casts are non heat treatable The braze floods like solder ! Filler rod number ls 4047 ?….. c 13% si. As with silicon bronze ( actually silicon copper 3.5 si. Some mn , ballance cu ) this silicon copper tig brazes & welds easily as jody has shown. Qv clips