Maybe you don't weld titanium yet...but the these tips and techniques still apply for taking a welding test for aerospace. Good luck!

Back around 1979, I was a pipe welder on a nuclear plant and looking for a change.

So I decided to try taking an aerospace welding test at a Lockheed plant.

I had never welded aluminum before and part of the test was aluminum so .... I failed it big time.

Ironically, after about 10 years of working more nuclear plants, fab shops, and paper mills, I got into the aerospace welding industry.

And even more unlikely, went on to become the manager over training and certification at Delta Airlines TechOps MRO in Atlanta GA

I learned a lot on that job and I am glad to share some tips I learned for passing a titanium welding test to AWS D17.1 specs.

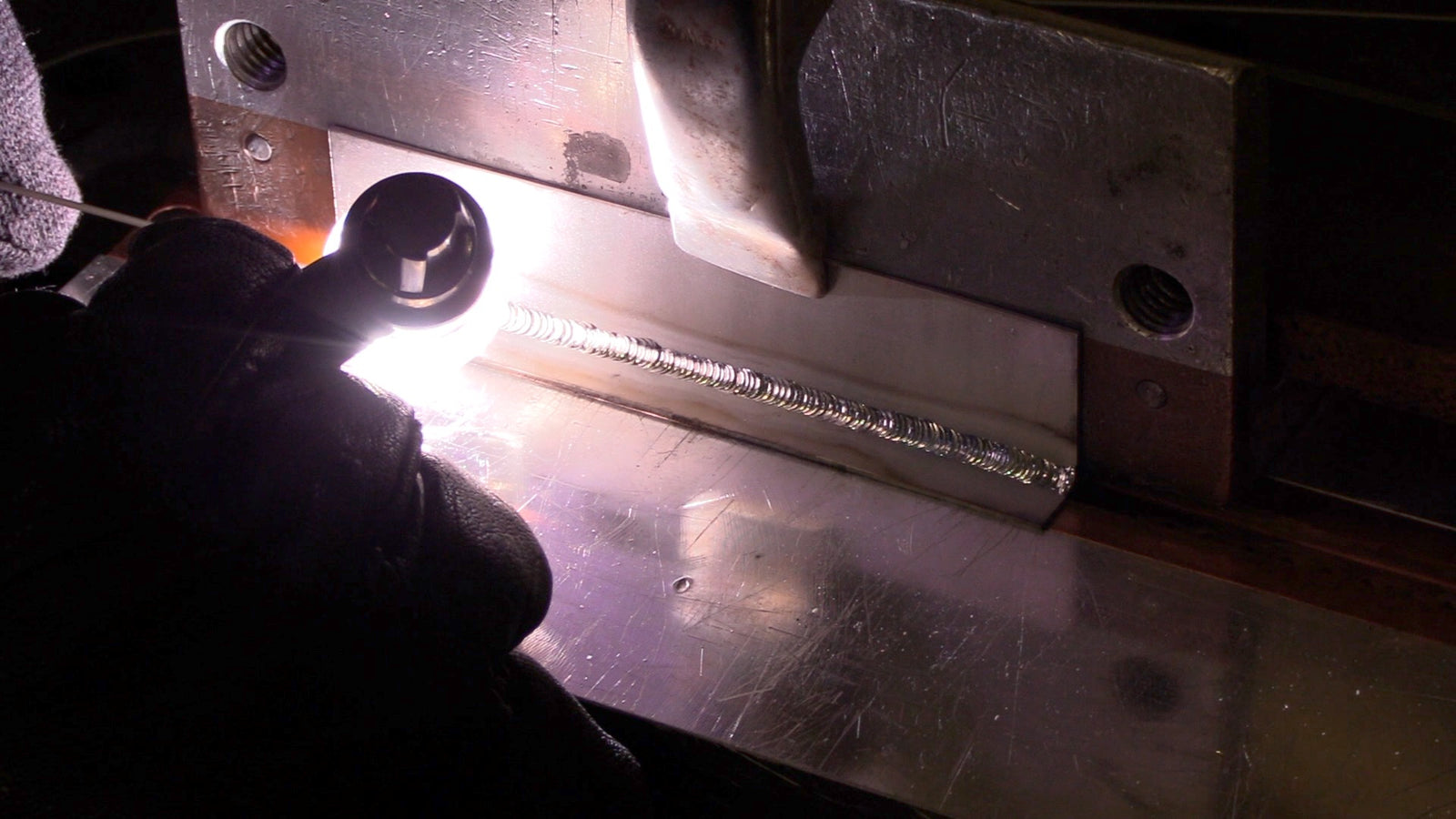

This weeks video shows a Titanium tee joint along with the main tips I learned along the way.

One thing you need for Titanium is a bigger and better cup than you might use for other metals.

Back in the day, there were no good cups for titanium and we would have large cups machined out of teflon material.

Then we would pack them full of copper wool or other diffuser material and by trial and error, figure out what worked.

Now we have great cups that work much better right out of the box.

If you need to weld titanium, inconel, 4130, tool steel, stainless, or any superalloy, where gas coverage is super important...

check out the Furick SG13 clear cup and the BBW

Aerospace welding certification tests are typically given using 4130 chromoly, 17-7ph stainless, inconel 718, 6061 aluminum, AZ31B magnesium, 6AL4V titanium, and Haynes 188

These 2 videos are on titanium weld tests in the .038"-.040" thickness range and are typical tests that you might be required to take in the aerospace welding industry.

Gas coverage is one of the most important issues when TIG welding titanium so a large cup with secondary diffuser screens like the Furick SG 13 or BBW is needed to prevent discoloration.

AWS D17.1 specifies certain discoloration requirements so a large cup like the furick SG13 or the BBW are very helpful tools to help achieve the silver discoloration limitations of D17.1 aerospace welding spec.

The chill block purge fixture is also an important detail since it helps the titanium cool faster.

I personally prefer to place the chill bars around 1/4" away from the toe of the weld so that the weld does not cool too quickly and thereby not allowing enough time for any porosity to outgas.

The great thing about kits is that you can be sure everything will fit your torch.

All you need to do is identify your TIG torch with the graphic below.

1 comment

Jody

I cant wait to watch your videos. You are fantastic teacher. I have been welding on and off for years but I have learned more watching your videos than I ever have. I’m trying to save up some cash for my own but life has been getting in the way. oh well I’ll get there.

Thanks for all the hard work you put into these videos.

Mark